- About

- Core Products

- undefined

- Core Products

- Inch

- undefined

- Inch

- All-Metal (Inch)

- undefined

- All-Metal (Inch)

- Cone Type (Automation)

- Full Hex Center Locknut

- Jam Hex Center Locknut

- Jam Hex Top Locknut

- Acorn Center Locknut

- Flanges (Inch)

- undefined

- Flanges (Inch)

- Top Lock Flange (TechPlus)

- Cone Top Flange

- Center Lock Flange

- Free Spinning Flange Nut Type

- Serrated Flange

- Collars (Inch)

- undefined

- Collars (Inch)

- Thin Cone Collar Jam Locknut

- Collar Plus and Thin Collar

- Nylon Insert (Inch)

- undefined

- Nylon Insert (Inch)

- Flange Nut

- Full Hex NE Nut

- Jam Hex Nut

- Heavy and Thick Hex NU

- Heavy Jam Hex NTU

- Small Hex & Machine Screw

- Acorn NKM & NKE

- Wing Nut WCA

- Locking Thread LOADNut

- Metric

- undefined

- Metric

- All-Metal (Metric)

- undefined

- All-Metal (Metric)

- Cone ASME B18.16 M

- Full Hex Center Lock DIN 934

- Cone ISO 7042, CL 10 & 8

- Hex Collar DIN 934

- Flanges (Metric)

- undefined

- Flanges (Metric)

- Top Lock Flange TechPlus DIN 6927

- Cone Flange ISO 7044

- Center Lock Flange DIN 6927

- Nylon Insert (Metric)

- undefined

- Nylon Insert (Metric)

- Flange Nut DIN 6926

- Made To Order

- undefined

- Made To Order

- All-Metal (Inch)

- undefined

- All-Metal (Inch)

- Cone Top Flange

- All-Metal (Metric)

- undefined

- All-Metal (Metric)

- Cone DIN 980V

- Jam Hex Center Lock ISO 4035

- Jam Hex Top Lock ISO 4035

- Flanges (Metric)

- undefined

- Flanges (Metric)

- Cone Top Flange

- Nylon Insert (Metric)

- undefined

- Nylon Insert (Metric)

- Thick Hex Nut ISO 7041

- Full Hex Nut ISO 7040

- Flange Nut ISO 7043

- Flange Nut ISO 12125

- Thin Hex Nut ISO 10511

- Collars (Metric)

- undefined

- Collars (Metric)

- Hex Collar DIN 934

- Specials

- Tech Support

- undefined

- Tech Support

- Custom Engineering

- Application Services

- Troubleshooting

- Inch Analysis

- Metric Analysis

- Mating Parts

- Videos

- Quality

- undefined

- Quality

- Customer Satisfaction

- Material Test Report

- Decision Rule of Conformity

- News

- Contact

- Request Quote

Manufacturing Processes

Manufacturing Processes

Installing Locking Elements

The core competency by Aztech Locknut Company is the installation of locking features in All-Metal Locknuts. Beginning in the mid 1970’s experience and development has grown to a level that now incorporates highly technical press machines and testing equipment. Aztech has refined the approach to impressing nuts such that for each product group, the highest quality deflection is installed and greatest part to part consistency is achieved.

Tooling works in concert with machines as integral sensors relay information to the machine that assures each cycle is consistent & complete. “Smart” processors determine the machine operating speed to maximize the output every hour with minimal required operator oversight. No tools quick change and “First Part Good” set-up technology means Aztech is the small lot specialist. Capabilities range from #6 through 4”.

Locknut Torque Test Machines

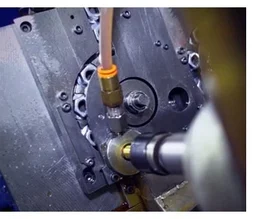

Fully automated parts handling allows for fast cycle rates with low operator work loads. The precision, consistency and variety of turning configurations of CNC allows Aztech to provide great diversity in high tolerance parts. Size capacity ranges from 5/8” through 4” nut size.

The most beneficial advancement in the locking process is the production floor torque testing machines. Our custom designed machines work in concert with the locking machine & tooling system and visually guide the operator adjustments to center the prevailing torque. The torque test machines are precise and record all results, removing data entry errors. Machines handle standard locknuts in size ranges from #4 through 4”.

CNC TurningFully automated parts handling allows for fast cycle rates with low operator work loads. The precision, consistency and variety of turning configurations of CNC allows Aztech to provide great diversity in high tolerance parts. Size capacity ranges from 5/8” through 4” nut size.

Nut Tapping

High speed, automatic feed machines deliver nuts with the typical 6 slots or slits in a variety of depths and width. Size ranges from #6 through 7/8”.

Aztech utilizes a variety of tapping machines, from standard multi spindle bent shank to specialized high precision electronic. Capacity ranges from #6 through 3”.

Slitting / SlottingHigh speed, automatic feed machines deliver nuts with the typical 6 slots or slits in a variety of depths and width. Size ranges from #6 through 7/8”.