You can’t be in the locknut business very long without encountering someone having problems with locknuts in their applications. When a locknut manufacturer’s registered quality system includes rigorous quality controls, their parts pass the qualification tests, and there are still problems on the customer’s assembly line, what happened? The short answer is that sometimes there are misapplications of locknuts.

A free-spinning nut is relatively tolerant of assembly conditions; locknuts are sensitive to assembly conditions. It’s not reasonable to expected a locknut to work in an application simply because a free-spinning nut did. So, what can a free-spinning nut tolerate that a locknut can’t?

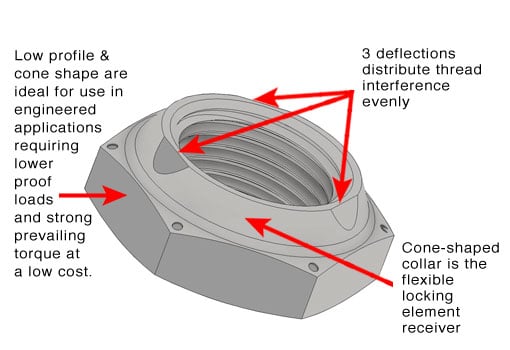

- Mating part thread quality – anywhere within the standard tolerance for pitch diameter (which allows some running clearance between threads), the free-spinning nut installs the same, while the prevailing torque of a locknut will vary with the pitch diameter of the mating part.

- Assembly speed and distance – the work of driving a locknut (prevailing torque times angle) is converted directly to heat at the points of sliding contact between the locknut and bolt. If too much heat is created faster than it can dissipate, the temperature of the threads will rise. Especially with large diameter close clearance thread class parts, this temperature rise will cause thermal expansion, which can cause runaway torque and assembly seizure prior to achieving the desired clamping tension in the bolt. Free-spinning nuts have no prevailing torque, and so no work is converted into heat until the assembly starts to clamp, and then the angle from starting clamp to assembly complete is usually small enough to limit the heat that is generated to insignificant.

- Nut/bolt material mismatch – for all-metal locknuts, the material properties of the locknut and the bolt should be similar, so they can share the load of the thread interference. If one is softer/weaker than the other, the softer component will wear faster as it yields at a lower stress level. It may not be intuitive, but the prevailing torque of a mismatched all-metal locknut assembly will decay faster than that of two softer, matched components. Since there is no thread interference for a free spinning nut, this effect does not exist with them.

- Start thread condition – Since the threads of a free-spinning nut are not loaded until the assembly starts clamping, the only condition on the start thread of the mating part is that it can accept the ring-type GO gage for the thread specification. For locknuts, the start thread of the mating part (bolt) should have a chamfer. With all-metal locknuts the start thread will be loaded by the thread interference, and if the thread section is too thin, it can bend or break off and contaminate the assembly to the point of seizure. With nylon insert locknuts, the insert can be pushed out of the nut before the thread form is impressed into it. The start thread chamfer for locknut mates should be per the description in ASME B18.2.1 Hex Cap Screw Point

“Point shall be chamfered or rounded at manufacturer’s option from approximately 0.016 in. below the minor diameter of the (bolt) thread. The first full formed thread at major diameter is located a distance no greater than 2 times the thread pitch from the end of the screw. This distance is to be determined by measuring how far the point enters into a cylindrical NOT GO major diameter ring gage (reference Gage, ASME B1.2, Page A-80).”

Most application problems resulting from a locknut replacing a free-spinning nut in an assembly can be traced back to one of these conditions. If the condition can be removed, the assembly will be successful.