The prevailing torque in prevailing torque locknuts comes from localized plastic deformation to an interference fit with continuous sliding during assembly. Let’s break this down.

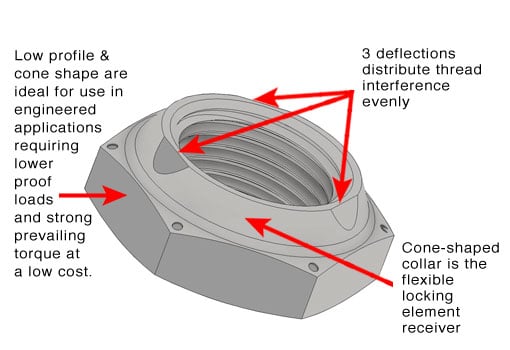

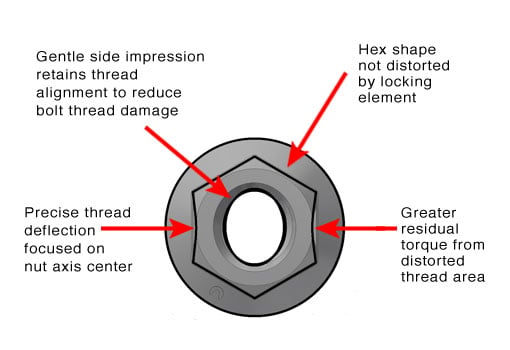

Localized plastic deformation – Some of the starting threads need to be able to accept the mating part (bolt, say) before the prevailing torque begins. The interference is therefore localized to not include the immediate start of the assembly. For nylon insert locknuts, the interference is only in the nylon ring, and the metal part of the nut is free-spinning; but the interference is the entire internal circumference of the nylon ring. For all-metal locknuts, the threads are plastically deflected such that there are points of interference (1, 2, 3, or 6 points of interference, depending on the configuration of the deflection) with the threads of the mating part.

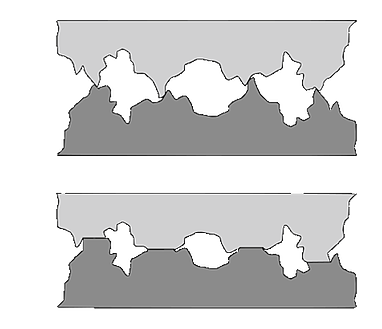

Interference fit – the threads of a prevailing torque locknut have negative clearance (there is contact and deflection) with the mating part.

Continuous sliding – contacting thread surfaces of the locknut and bolt are sliding across each other as the nut is installed.

The normal forces that result from the interference fit have three effects:

- They cause localized plastic deformation on the contact areas of the threads until the contact areas are large enough to support the forces (resulting point stresses are below the yield stress). This deformation occurs over a number of rotations of the locknut on the bolt, and causes the prevailing torque to “wear out”.

- They knock down the minuscule asperities on the thread surfaces to make the surfaces smoother.

They combine with the coefficient of friction of the surfaces to create tangential friction forces acting at the pitch diameter, which become the prevailing torque.

Prevailing Torque Decay

Because of these effects, when the assembly is behaving correctly the prevailing torque of a prevailing torque locknut is constantly decaying as the locknut is installed.

- The rate of decay depends on

- The hardness of the materials

- The degree of interference

- How the interference is distributed across the surface of the threads

So, at the same prevailing torque levels, softer material and/or more localized deflections will result in the prevailing torque wearing out at a higher rate.

Prevailing Torque Variation

There are several normal sources of variation in the prevailing torque of a locknut, including

– Part-to-part variations within a lot of the mating part (bolt)

- pitch diameter

- thread defects (nicks, dents, dings)

– Part-to-part variations within a lot of the locknut component (the nut before deflection)

- pitch diameter

- exterior dimensions (height, concentricity of the thread to the hex, width across flats, concentricity of the nylon ring to the thread, diameters and thickness of the nylon ring)

– Process variations

- location of the deflection (especially relative to where the thread exits the top the locknut, for axially deflected all-metal locknuts)

- degree or depth of the deflection

The effect of these variations is reflected in the prevailing torque

Prevailing Torque Limits

When defining limits on prevailing torque, the normal effects of decay and variation should be considered.

A well-developed deflection mechanism and deflection process can minimize the decay and variation, but they will always be present to some degree, and decay and variation controls (special nut thread tolerances, special tighter nut dimensional tolerances, special test bolts, complex process tooling, etc.) can add prohibitive expense to a process.